INDUSTRIAL LASER TRENDS

CHOOSE A CATEGORY

- All

- Co2 laser solutions

- FAQ

- Fiber laser solutions

- Uncategorized

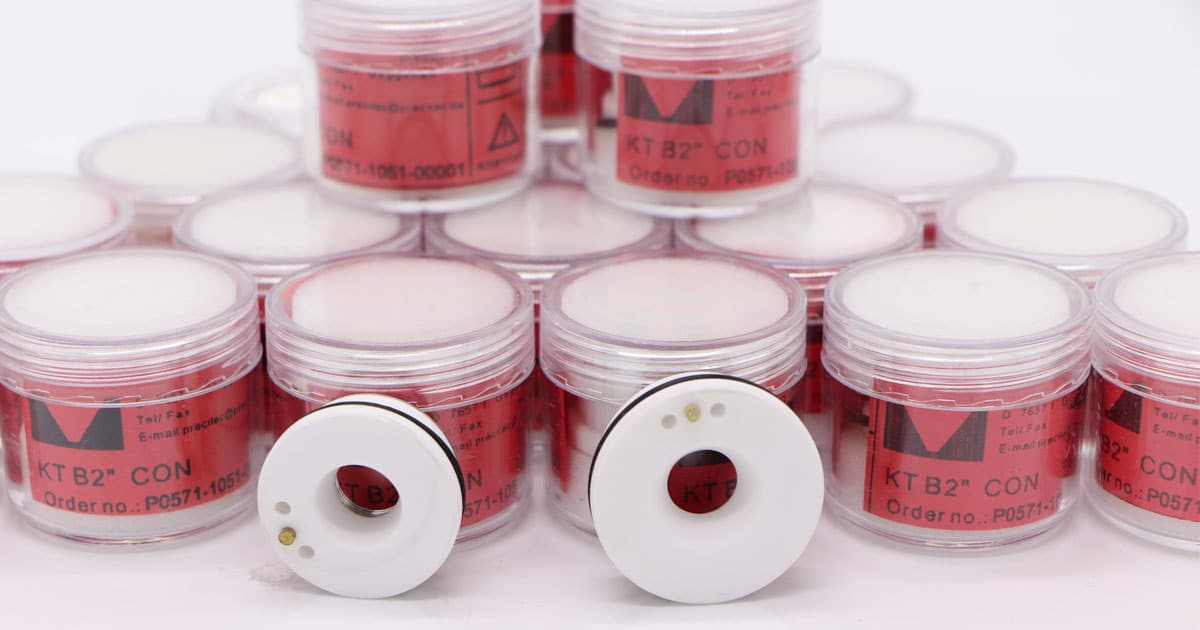

Ceramic Ring– An important part of the cutting head of Optical Fiber Laser Cutting Machine

The fiber laser cutting machine has three major consumables: protective lenses, nozzles, and ceramic rings. The ceramic ring is an important part of the cutting head on the fiber laser cutting machine, which is used to transmit the electrical signals collected by the nozzles of the laser head and stabilize ...

General problems and solutions of protective lenses with laser cutting head

As we all know, the laser cutting head is the most important operating part of the laser cutting machine, the laser cutting head has the characteristics of high precision and valuable. The optical element plays an important role in the components of the laser cutting head. In the process of ...

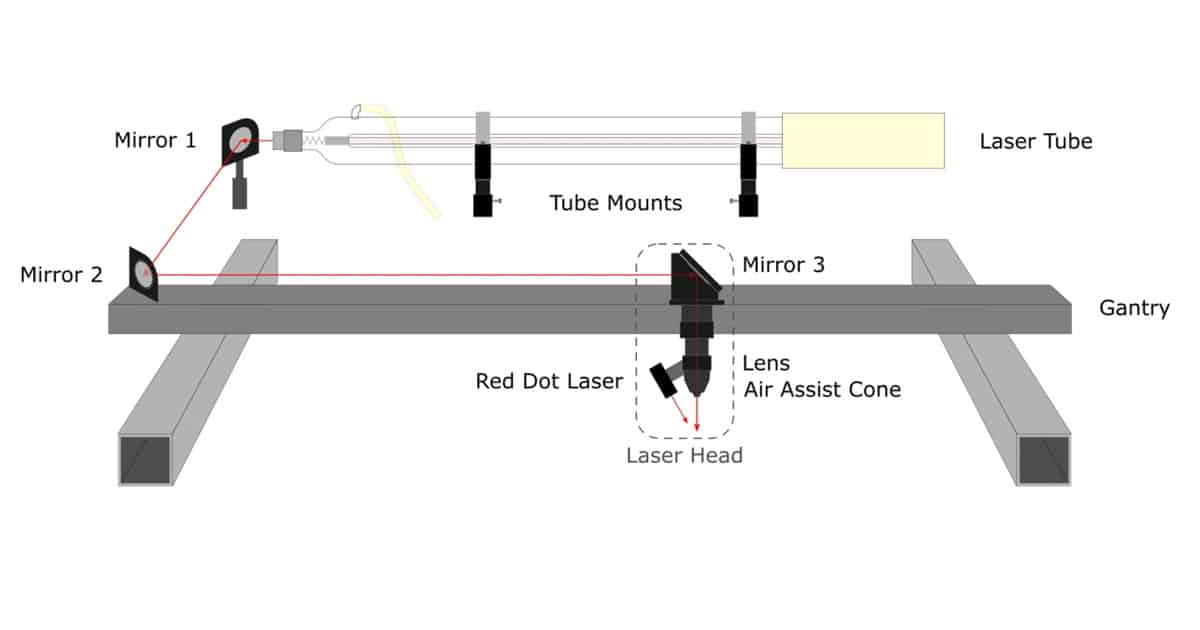

How to adjust the laser path of laser engraving machine

The laser power is transmitted by a fixed path controlled by the lens and mirrors. However, when the machine has been working for a long time or longer transportation the light path will slightly deviate. When the deviation is serious, the copper nozzle may not be able to emit light, ...

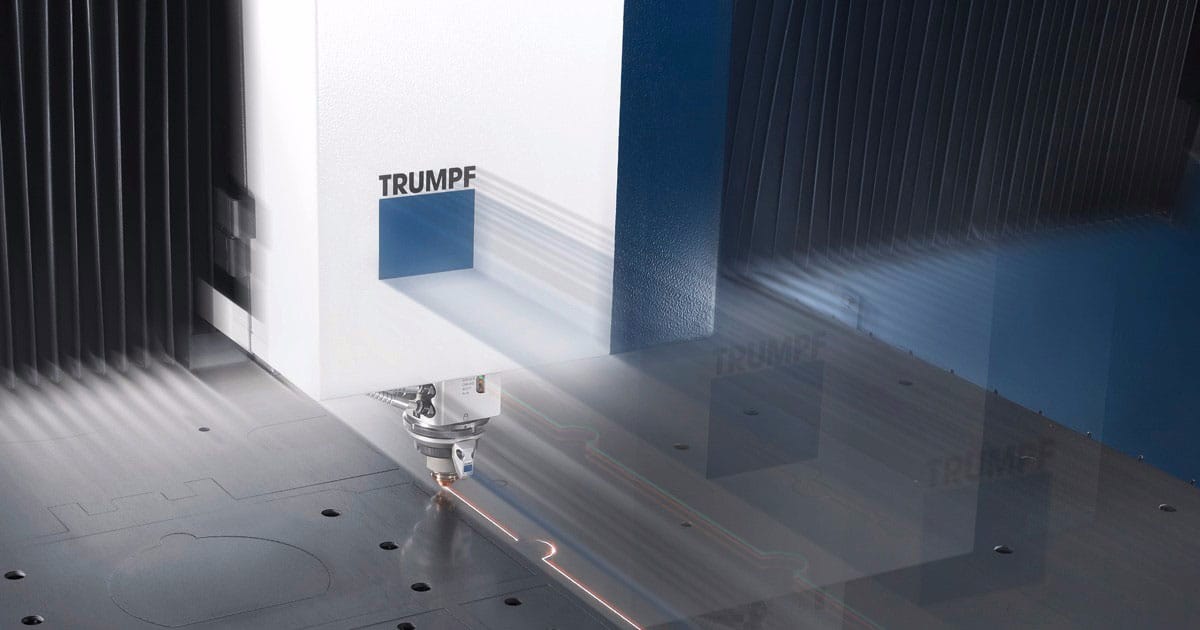

What Are The Advantages Of Fiber Laser Cutting Machine

All laser cutting processes have their own inherent advantages and disadvantages, but it appears that the benefits of fiber laser cutting machines far outweigh that of any of the other processes. From the practice we have summarized advantages : 1. High cutting accuracy: laser cutting machine positioning accuracy 0.05mm, repeated ...

CO2 laser lens cleaning

The focusing lens of the laser cutting machine is a key optical element, and its cleanliness directly affects the processing performance and quality of the laser cutting machine.

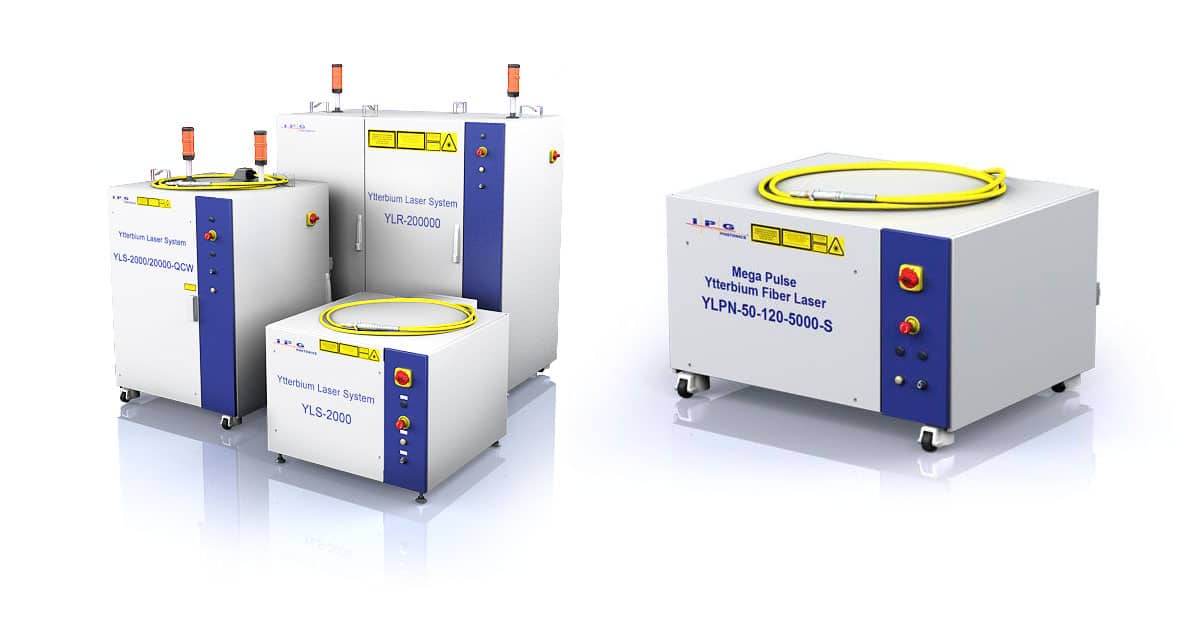

Guide maintenance of fiber lasers in Summer

After the Beginning of Summer, the temperature gradually increased and the air humidity increased. The laser source is easy to break down in the summer. According to the statistical results, most of the faults of high power laser are closely related to the operation sequence of users and the operating ...

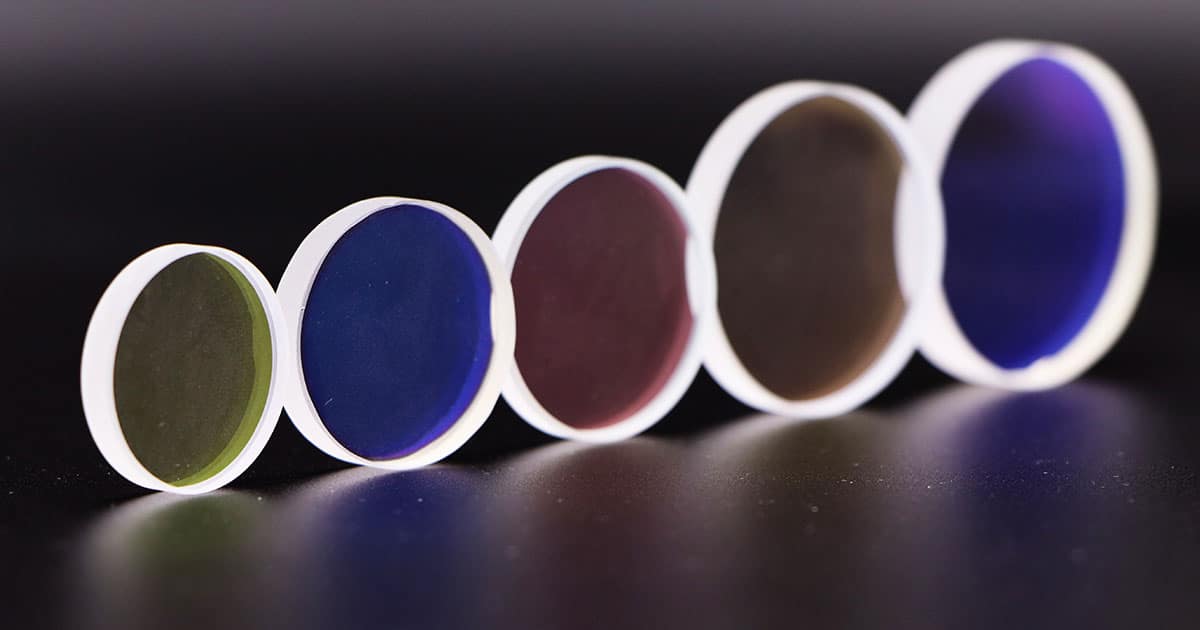

Cleaning and maintenance of Fiber laser lenses

Laser Safety Glasses · You should handle optics in a clean, low-dust, temperature-controlled ... each optic and place onto a clean lens tissue or into an optical storage container.

Daily maintenance of CO2 laser tube

Co2 glass laser tube is the core component of laser cutting machine, laser tube is divided into domestic and imported laser tube, the life of domestic laser tube is usually 5000 hours ~ 6000 hours, The life of imported laser tube can reach 8, 000 to 10, 000 hours, and ...

How to Choose the Fiber Laser Cutter Nozzle

The laser nozzle is one of the most important parts of a fiber laser cutting machine. It is installed at the bottom of the laser head, laser power and high-pressure airflow are emitted through the nozzle, which is related to the cutting quality and service life of the laser cutting ...