CO2 laser tube is a gas laser with CO2 gas as the working material.

The discharge tube is usually made of glass or quartz, filled with CO2 gas and other auxiliary gases (mainly helium and nitrogen, and usually a small amount of hydrogen or xenon); the electrode is usually made of nickel hollow cylinder; one end of the resonant cavity is a gilded total mirror, the other end is a partial mirror made of germanium or gallium arsenide.

When a high voltage is applied to the electrode (usually DC or low-frequency AC), a glow discharge is produced in the discharge tube, and there is a laser output at one end of the germanium mirror, whose wavelength is in the mid-infrared band near 10.6 microns;

The continuous output power of 40 to 60 watts can be obtained in the discharge zone with a length of about one meter.

Advantages:

- It makes use of the transition between vibrational and rotational energy levels of CO2 molecules. It has rich spectral lines and dozens of laser output lines near 10 microns.

The high-pressure CO2 laser discovered in recent years can even achieve continuously tunable output from 9 to 10 microns.

- Its output band happens to be the atmospheric window (that is, the atmosphere has high transparency to this wavelength); in addition, it also has the advantages of high optical quality, good coherence, narrow linewidth, stable operation, and so on.

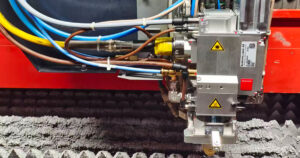

Therefore, it has many applications in the national economy and national defense, such as processing (welding, cutting, drilling, etc.), communication, radar, chemical analysis, laser-induced chemical reactions, surgery, and so on.

- It has relatively large power and high energy conversion efficiency.

A general closed-tube CO2 laser can have a continuous output power of tens of watts, which is much higher than that of other gas lasers, while a transversely mobile electrically excited CO2 laser can have a CW output of hundreds of thousands of watts.

In addition, the transverse atmospheric pressure CO2 laser also achieves a high level of energy and power from the pulse output, which is comparable to that of the solid-state laser.

The energy conversion efficiency of CO2 lasers can reach 30-40%, which is also higher than that of ordinary gas lasers.

Suggestions for prolonging span life:

First, when in use, please turn on the cooling water firstly, the principle is low input and high output, adjust the position of the outlet pipe to ensure that the cooling water is full of cooling pipe, there can be no bubbles in the pipe and then turn on the power supply.

Requirements: soft water (distilled water or pure water) is used for cooling water, and pay attention to the water temperature of cooling water, the water temperature should be controlled in the range of 25 ℃-30 ℃, not too high or too low, especially in summer, once the water temperature is found to be too high, the cooling water should be changed in time or stop for a period of time: the cooling water in cold areas should not freeze, especially after the laser is shut down, the cooling water should not be stored in the laser tube.

To prevent the cooling water from freezing and causing it to explode.

(special attention: for users using alternating current, the cooling water tank must be grounded.).

Second, the two supporting holders should be on the point that the total length of the laser tube is 1/4, to ensure the flow of cooling water in 2L-4L/ minutes; otherwise, the effect is not good, it will cause mode hopping, and several points of the light spot will lead to a drop in power; the return water outlet of cooling water must be covered by water in the water tank, otherwise, the cooling water in the laser tube will be filled with dissatisfaction every time the machine is turned off.

Third, pay attention to protect the output window of the laser to prevent the smoke generated in the course of working (including the process of debugging the optical path) from being sputtered to the surface of the output window, so as to prevent the outer surface of the output window from being contaminated and the power will be reduced. at this time, skimmed cotton or silk cloth can be dipped in anhydrous alcohol to gently wipe the outer surface of the output window.

Fourth, in the process of debugging, adjust the laser support point or rotate the laser azimuth to achieve the best output effect, and then fix the laser.

Please pay attention to avoid the accumulation of dust near the high-voltage electrode, keep it dry and keep the high-voltage end as far away from the metal as possible to prevent high-voltage fire discharge.

Sixth, during the use of the laser, no scale can be formed in the cooling tube, so as to avoid clogging the cooling water and deteriorating the heat dissipation effect.

Once found, the cooling pipe can be cleaned with 20% dilute hydrochloric acid to remove the scale.

The laser is made of glass and is fragile. Avoid local force when installing and using.

Eighth, rationalize the application of laser tubes to save laser energy. The best working current of the laser tube is 16mA.