Introduction

These are manufactured according to particularly stringent quality specifications.

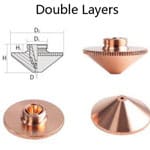

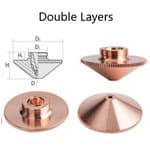

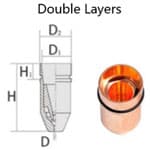

Double-layer nozzles are generally used for oxidative cutting, using oxygen as an auxiliary gas, usually used for cutting

carbon steel.

Precitec

| Ref No. | Compatible with cutting head |

Laser nozzle DE HP1.5″P0591-569-00008/P0591-561-00010/P0591-562-00012 P0591-563-00015/P0591-564-00018/P0591-565-00020 P0591-566-00025/P0591-568-00030 |

Nozzle for cutting heads ProCutter 1.0, ProCutter 2.0 (with KT XB), LightCutter, HPxx, MiniCutter2D

suitable for ceramic parts KT B2” CON and KT XB |

Laser Nozzle DE HP1.5″ outside cone-shapedP0591-571-00010/P0591-572-00012/P0591-573-00015 P0591-574-00018/P0591-575-00020/P0591-576-00025 P0591-577-00030/P0591-578-00040/P0591-579-00050 |

Nozzle for cutting heads ProCutter 1.0, ProCutter 2.0 (with KT XB), LightCutter, HPxx, MiniCutter2D

suitable for sensors CM, Hx suitable for ceramic parts KT B2” CON, KT XB |

| Picture | Model | Dia

mm |

Height

mm |

Caliber

mm |

Thread | OEM number |

|

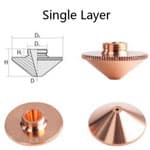

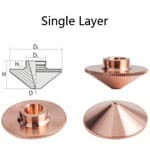

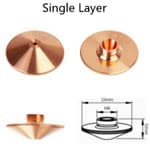

A-D28H15

Single-layer |

28 | 15 | 0.8-5.0 | M11 | P0591-570-00008 |

|

A-D28H15

Double layer |

28 | 15 | 0.8-5.0 | M11 | P0591-002-00008 |

|

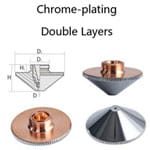

A-D28H15

Chrome-plated Single layer |

28 | 15 | 0.8-5.0 | M11 | PC0591-570-00008 |

|

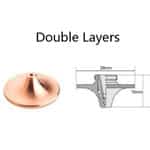

A-D28H15

Chrome-plated Double layer |

28 | 15 | 0.8-5.0 | M11 | PC0591-002-00008 |

|

B-D28H11

Single-layer |

28 | 11 | 0.8-5.0 | M11 | |

|

B-D28H15

Single-layer |

28 | 15 | 0.8-5.0 | M11 | P0591-563-00015 |

|

B-D28H15

Double layer |

28 | 15 | 0.8-5.0 | M11 | P0591-002-0000 |

|

B-D28H15

Chrome-plated Double layer |

28 | 15 | 0.8-5.0 | M11 | P0591-569-00008 |

|

C-D28H15

Single-layer |

28 | 15 | 0.8-4.0 | M11 | |

|

C-D28H15

Double layer |

28 | 15 | 0.8-5.0 | M11 | |

|

C-D28H15

Chrome-plated single layer |

28 | 15 | 0.8-5.0 | M11 | |

|

C-D28H15

Chrome-plated double layer |

28 | 15 | 0.8-5.0 | M11 | |

|

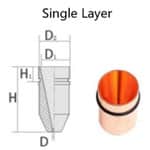

D-D28H22.5 Single layer | 28 | 22.5 | 1.5 | M11 | |

|

3D-D14H15

Single-layer |

14 | 15 | 0.8-2.0 | M9 |

Raytools

| Picture | Model | Dia

mm |

Height

mm |

Caliber

mm |

Thread |

|

A-D32H15

Single-layer 120GJT0510/120GJT0512/120GJT0515 120GJT0520/120GJT0525/120GJT0530 120GJT0535/120GJT0540/120GJT0545 120GJT0550 |

32 | 15 | 0.8-5.0 | M14 |

|

A-D32H15

Double layer

|

32 | 15 | 0.8-5.0 | M14 |

|

A-D32H15

Chrome-plated Single layer |

32 | 15 | 0.8-5.0 | M14 |

|

A-D32H15

Chrome-plated Double layer 120GJT0610/120GJT0612/120GJT0615 120GJT0620/120GJT0625/120GJT0630 120GJT0635/120GJT0640/120GJT0645 120GJT0650 |

32 | 15 | 0.8-5.0 | M14 |

|

B-D32H15

Single-layer |

32 | 15 | 0.8-4.0 | M14 |

|

B-D32H15

Chrome-plated Double layer |

32 | 15 | 0.8-5.0 | M14 |

|

C-D32H15

Single-layer |

32 | 15 | 0.8-5.0 | M14 |

|

C-D32H15

Chrome-plate Single-layer |

32 | 15 | 0.8-5.0 | M14 |

|

C-D32H15

Chrome-plated Double layer |

32 | 15 | 0.8-5.0 | M14 |

|

D-D10.7H22.2

Single-layer |

10.7 | 22.2 | 0.8-4.0 | |

|

D-D10.7H22.2

Double layer |

10.7 | 22.2 | 0.8-4.0 | |

|

3D-D15H19

Single-layer |

15 | 19 | 0.8-3.0 | M8 |

Bodor

| Picture | Model | Dia

mm |

Height

mm |

Caliber

mm |

Thread |

|

A-D28H15

Single-layer |

28 | 15 | 0.8-4.0 | M11 |

|

A-D28H15

Double layer |

28 | 15 | 0.8-4.0 | M11 |

|

B-D32H15

Single-layer |

32 | 15 | 0.8-5.0 | M14 |

|

B-D32H15

Double layer |

32 | 15 | 0.8-5.0 | M14 |

Trumpf

| Picture | Model | Dia

mm |

Height

mm |

Caliber

mm |

Thread |

|

ECE124561 ,124562,966809 237497,237501, 1253211 126933,942742 |

24 | 10 | 0.8-3.0 | M8 |

|

ECEA-D24H10 Double layer |

24 | 10 | 0.8-2.0 | M8 |

|

EAA1324858,1324860,1324861 1324863,1324864, 1324865 1324866,1324867 |

25 | 15.5 | 0.8-2.3 | M12 |

|

EAU2059462,2060001,2060004 2060025,2253595

|

20 | 15 | 2.5-10.0 | M10 |

|

EAK1835747 |

25 | 15.5 | 2.5-4.0 | M12 |

|

EAQ1809091,1809421,1886199 |

25 | 15.5 | 6.2-9.5 | M12 |

|

|

EAN |

25 | 15.5 | 1.7-2.5 | M12 |

Bystronic

| Picture | Model | Dia

mm |

Height

mm |

Caliber

mm |

Thread |

|

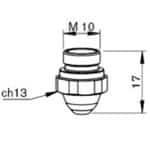

A-D13H17

NK Double layer |

13 | 17 | 1.0-3.0 | M10 |

|

A-D13H17

HK Single layer |

13 | 17 | 0.8-4.0 | M10 |

|

B-D13H17 | 13 | 17 | 0.8-3.0 | M10 |

|

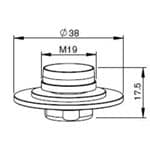

10046030 | 38 | 17.5 | M10 | |

|

2-08700 | 52 | 9.5 | M12 | |

|

10032930 | 26 | 30.5 | ||

|

2-08701 | 28 | 30.5 |