The market for laser machines is still growing at a high speed.

The laser machine is realized by a complete set of laser processing equipment.

The complete set of laser machines is integrated with a laser, numerical control system, optical parts, mechanical parts, and electrical control parts.

The numerical control system is one of the core components and belongs to the “brain” part of the whole machine. It coordinates and controls all the accessories.

Increasing the market share of laser control systems and other core components and improving the transformation of industrial automation are important components of implementing the deep integration of information technology and the manufacturing industry, equipment autonomy, quality improvement, and efficiency improvement.

Since the implementation of reform and opening up in China, after long-term efforts in several stages, such as the introduction, absorption, independent development, and industrialization of numerical control technology, China’s numerical control system industry has grown from scratch and formed a number of numerical control system backbone enterprises. It has laid the foundation of the numerical control system industry in China.

The laser machine is a collection of advanced technologies of high-tech terminal equipment. This industry is the most concerned and has the most rapid development.

With the development of China’s economy and the in-depth implementation of the national strategy, the demand of the manufacturing industry for automatic and intelligent production modes is increasing day by day. China’s laser industry is in a period of rapid development, and the market demand of the laser industry is gradually turning to China. The domestic laser processing equipment market has maintained rapid growth. Data show that the domestic laser processing equipment market has increased from 37.1 billion yuan in 2016 to 69.2 billion yuan in 2021.

In 2021, the sales income of domestic laser processing equipment is about 77 billion yuan.

Development status of the laser subdivision industry

Laser marking industry

Laser marking is one of the important application fields of laser processing. It mainly uses a high energy density laser beam to etch the workpiece shallowly to vaporize the surface material or produce a color change reaction, leaving a lasting imprint or achieving the purpose of surface processing, such as texture treatment.

With the decline in the price of laser marking equipment and the extensive demand of the downstream market, China’s laser marking equipment industry has ushered in a period of rapid development in recent years. With the expansion of the downstream application field of laser marking and the rebound of the prosperity of the downstream industry, the sales scale of laser marking equipment in 2020 has increased rapidly and exceeded the 2018 level.

With the improvement of the localization and competition in the upstream CO2 laser and fiber laser market, the price of laser marking equipment falls, and the cost reduction is conducive to the further expansion of downstream applications.

At the same time, with the development of 5G communication industry and the rapid development of new energy vehicles, the demand for laser marking equipment in global consumer electronics, home, automobile industry and the Internet of things will be further released. The penetration of laser marking equipment in many industries will be improved.

Laser Cutting industry

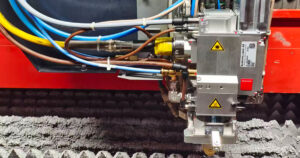

Laser cutting uses the laser beam output from the laser oscillator to focus through the focusing mirror to produce a laser beam with high focus and high energy to melt and evaporate on the material, and then use oxygen and other auxiliary gases to blow away the excess slag in the laser cutting seam and produce high heat, so as to achieve the purpose of cutting the material.

Because of the large energy per unit area, the laser can cut high-precision products with small slits.

Laser cutting equipment is used in a wide range of terminal industries in China, including machinery, automobiles, furniture, household appliances, electronic screens, and other fields.

With the improvement of the localization rate of high-power lasers in China and the rapid release of downstream market demand, the number of shipments of laser cutting equipment shows a rapid growth trend.

Laser Welding industry

As a modern welding technology, laser welding has the advantages of deep penetration, high speed, small deformation, low requirement for welding environment, high power density, not being affected by the magnetic field, not limited to conductive materials, no vacuum working conditions, and no X-ray in the welding process. Because of its unique advantages, it has been successfully applied to the precision welding of micro and small parts.

It is widely used in automobiles, ships, aerospace, and other high-end precision manufacturing fields.

Prediction of the Development Prospect of the Laser Industry

The main development trend of the laser industry in the future is ultra-fast laser will become the future development trend of laser industry industry will continue to develop in the direction of high precision and the industry will continue to develop in the direction of flexibility.

The laser processing control system is the brain of laser processing equipment. With the continuous development of laser processing equipment, the performance requirements of laser processing control systems are increasing daily. In the future, the application of laser processing control systems will develop toward high precision.

With the development and cost reduction of ultrafast lasers, such as picosecond and femtosecond, ultrafast laser processing will gradually replace traditional processing technology and be used in the processing of brittle materials. It is expected that ultrafast laser processing will become the main processing method for OLED screens, LCD screens, and high-end glass covers.

Laser processing control systems continue to develop in the direction of flexibility. In order to meet the individual needs of downstream users for products, respond to changes in the supply chain in time, and realize consumer-oriented flexible processing, laser processing equipment needs to have multi-function and high adaptability.

It can process different raw materials with product changes, determine the corresponding technological process according to different processing objects, and expand system modules with the emergence of new requirements.