INDUSTRIAL LASER TRENDS

CHOOSE A CATEGORY

- All

- Co2 laser solutions

- FAQ

- Fiber laser solutions

- Uncategorized

How to choose laser nozzles?

In the process of laser cutting, the laser nozzle is the most common wear and tear on the laser head, and it is also one of the most important parts in laser cutting. It is located at the bottom of the laser head and is closest to the workpiece. The ...

How to determine the focus position of laser cutting machine?

When the laser cutting machine is engaged in the cutting operation, there will be some differences in the cutting quality with different focus positions. Therefore, in order to further improve the cutting quality of the laser cutting machine, it is very important to adjust the focus position of the laser ...

Laser Cutting Machine Market is Expected to Experience Immense Growth

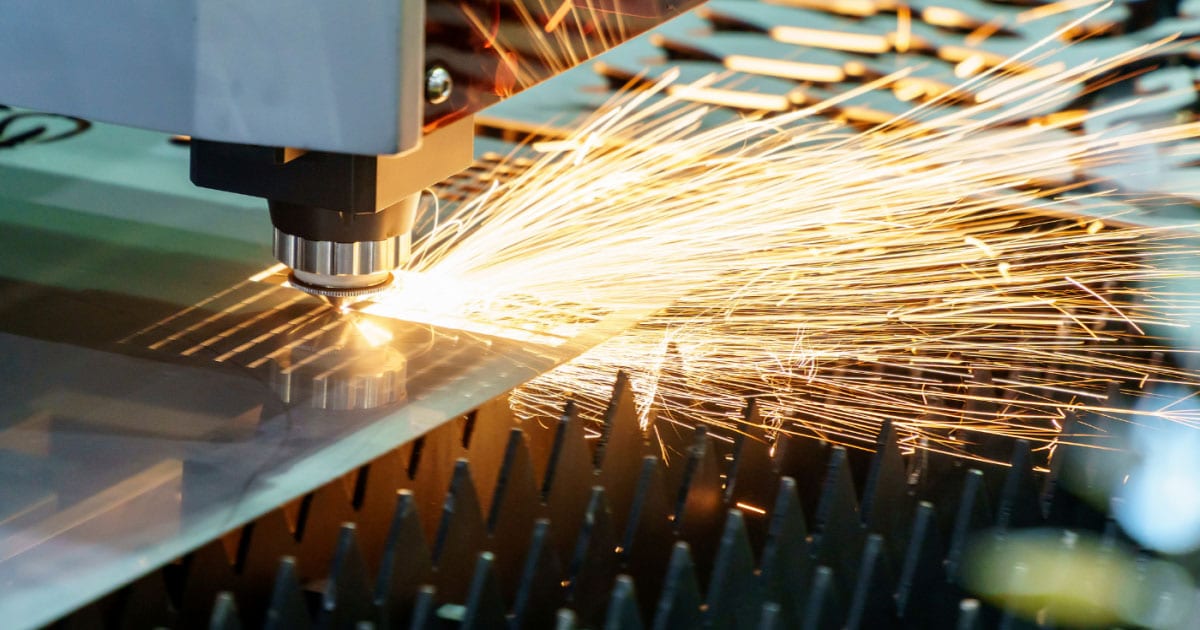

Laser Cutting Machine Market is Expected to Experience Immense Growth Laser cutting is a technology that uses lasers such as CO2, solid-state, and fiber to cut materials. Laser cutting machines are capable to cut materials ranging from steel to plastic with absolute precision. It is an important manufacturing tool required ...

What is Laser Cutting Machine?

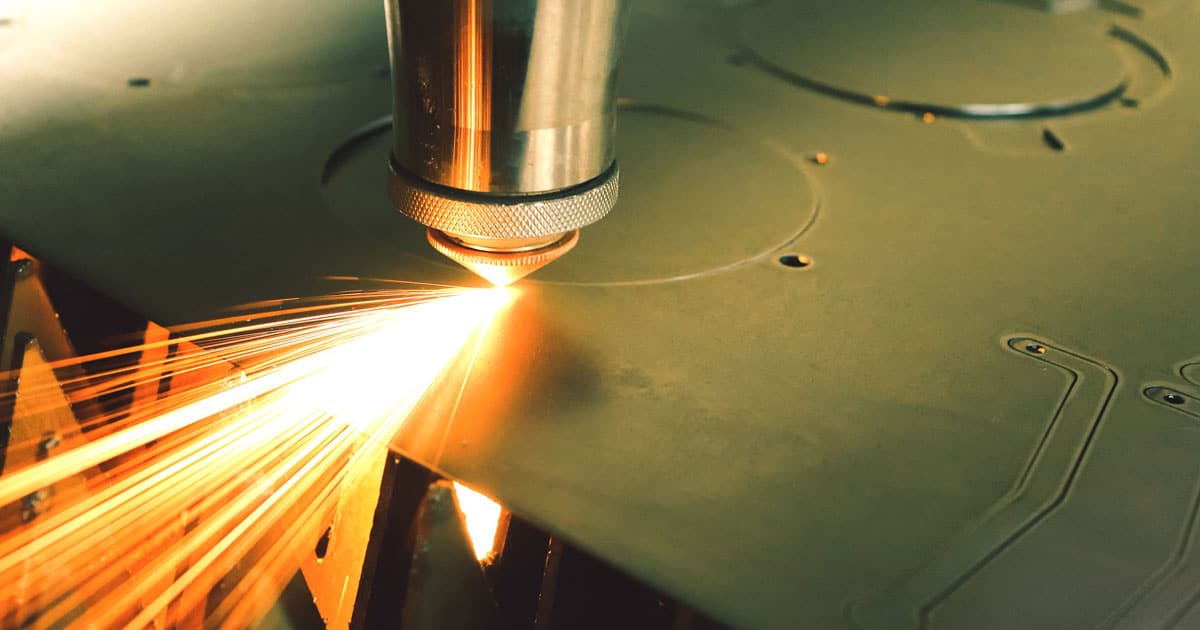

Laser cutting machines allow metal fabricators to create high-quality parts that require very little, if any, finishing work. As the high-powered laser is cutting, excess material is either melts, burns, or vaporizes away. A high-pressure jet of gas also blows away any debris, resulting in a highly finished surface cut. ...

Common Problems and Solutions of Laser Cutting

Laser cutting is widely used in automobile manufacturing and material processing due to its good precision, wide cutting range, high efficiency, strong processing ability and good flexibility. There are also some problems encountered in the laser cutting production : Burrs appear on the edge of the workpiece When laser cutting ...

CO2 VS. FIBER LASER – WHICH ONE SHOULD YOU BUY?

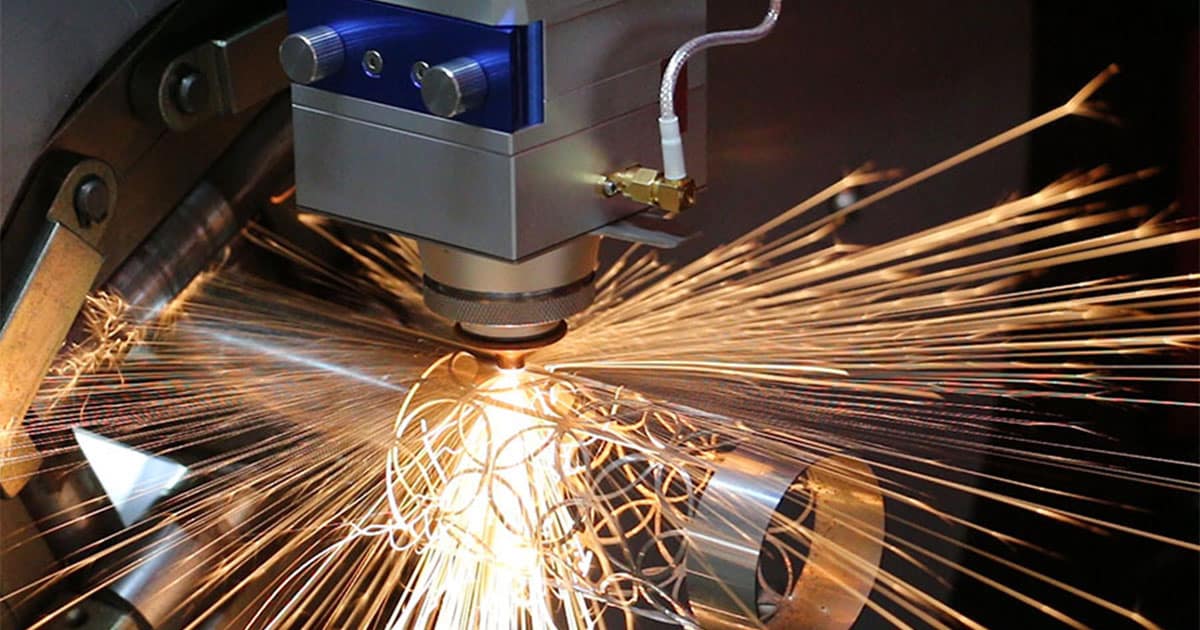

At present, there are five kinds of laser light sources: gas laser, solid-state laser, semiconductor laser, fiber laser and dye laser. Among them, CO laser and fiber laser are the most commonly used in the field of industrial processing. In recent years, fiber laser cutting technology has been widely used ...

How to choose auxiliary gas in the laser cutting process?

How to choose auxiliary gas? What aspects of cutting quality will be affected by different gases? Which auxiliary gas to choose for different plates? How to control the pressure of auxiliary gas? What is the purity requirement?

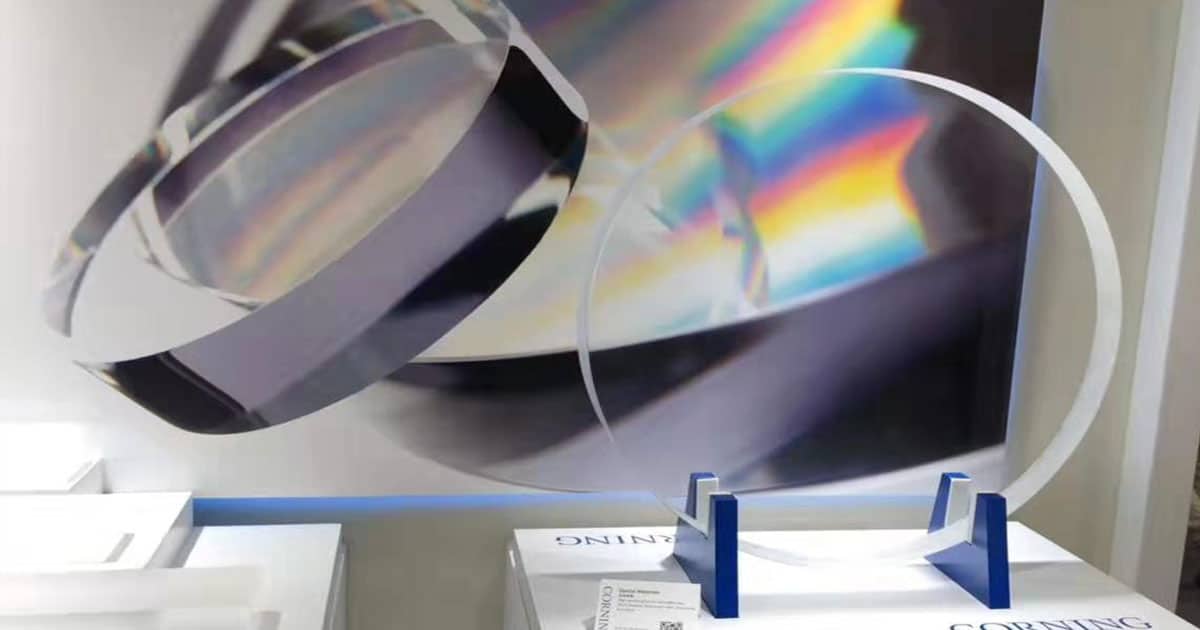

Brief Introduction Of Fused Silica

used silica material is not only an important basic material for optical fiber preforms, but the entire process of optical fiber production is also inseparable from fused silica products. Good raw materials are the guarantee for the production of stable quality optical fiber products.

Bystronic Trumpf Amada CO2 laser Upgrade to Fiber Laser

Do you dream of changing your CO2 laser cutting machine into a Fiber laser cutting machine? Do you feel bad because of the high-power consumption of CO2 laser cutting machines? Do you feel bad because of the high-running cost of CO2 laser cutting machines? Do you feel bad because of ...