Fused quartz, also known as quartz glass, is a supercooled liquid made from natural quartz,

including silica, crystal, etc., through high-temperature fusion.

Classification of fused silica

Fused silica generally includes two types: transparent quartz glass and opaque quartz glass. The SiO2 content in transparent quartz glass is greater than 99.95%, which is made by high-purity quartz powder or silicon tetrachloride as raw materials, and is melted at high temperature; the SiO2 content in opaque quartz glass is greater than 99.80%, which is made of ordinary quartz powder and quartz sand. The raw materials are melted at high temperatures.

In recent decades, the application fields of fused silica have become wider, which has promoted the rapid development of the fused silica industry, and many new varieties have been continuously developed. Such as powder optical grade fused silica glass, opaque fused silica glass, low hydroxyl fused silica glass and synthetic optical grade fused silica glass developed by HERAEUS in Germany. The cerium-doped tube, iron-doped tube and fused silica glass with ultra-high purity and wide ultraviolet transmission capability were developed by GEQUARTZ in the United States.

Fused silica glass tubes for electric light sources have been produced on a large scale in China, and some products have reached the advanced level of foreign countries, because their price advantages are extremely competitive.

Production status of fused silica

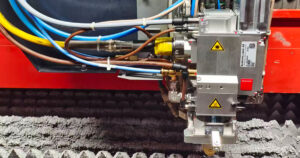

Donghai County, Jiangsu Province has large reserves of quartz raw materials and high purity, and is China’s silicon material industrial base. At present, the production process commonly used by the manufacturers of fused silica raw materials in Donghai County is: crush selected high-quality silica raw materials (SiO2 content> 99%), such as vein quartz, etc. into small particles, and heat them in a graphite rod heating furnace (using high-quality steel plate coils). It is melted in a cylindrical furnace body with a certain volume, directly cooled and then crushed and classified into blocks.

There are two major difficulties in the production of fused silica: one is that the melting temperature is high, the viscosity is large, and the bubbles are difficult to eliminate; the second is that the purity of fused silica must be improved to obtain excellent performance, and the total amount of impurities is less than one ten thousandth.

SiO2 has a high melting temperature and is easy to react with other substances to form silicate. Therefore, it is a major technical problem to select refractory materials that have good insulation effects and do not react with fused silica, and select refractory materials that do not affect the quality of fused silica in design research. At present, the heat preservation method adopted in the production of fused silica in my country is mainly self-heat preservation, that is, part of the non-fused quartz is used for heat preservation and heat insulation, so as to avoid the pollution of the fused quartz by refractory materials. The self-heat preservation process has poor heat preservation effect in actual production, and redness of the furnace shell often occurs. The self-insulation process not only wastes much energy, but also has a low production rate of fused silica and the quality is not easy to guarantee.

In terms of fused silica melting equipment, most enterprises in my country still use single-carbon rod resistance heating primary production equipment, and the control is still constant power heating, and the energy consumption in the melting process is relatively high.

In addition, the fused silica industry is a high energy consumption industry with a large demand for electrical energy, and energy consumption accounts for more than 50% of the production cost of fused silica. With the increasing contradiction between the supply and demand of electric energy, the production costs of fused silica manufacturers continue to increase, resulting in reduced profit margins and hindering the development of the industry. Improving product quality and reducing energy consumption have become an important way to improve the economic efficiency of enterprises.

Application and market overview of fused silica

Because of its excellent physical and chemical properties, fused silica is widely used in electronics, electrical appliances, military, aerospace, optical communications, electric light sources, chemical engineering, metallurgy, instrumentation, optical lenses, anti-corrosion materials and refractory materials.

Fused silica is widely used in high-tech fields: high-purity high-temperature resistant quartz glass tubes, high-purity coated crucibles, quartz glass for optical communications and quartz glass for lasers have all developed rapidly.

(1) Electric light source industry

Electric light sources convert electrical energy into light energy and are widely used in daily lighting, industrial and agricultural production, national defense, and scientific research. Common low-intensity energy-saving lamps, germicidal lamps and high-intensity Ley lamps, sodium lamps, metal halide lamps, infrared lamps, and ultraviolet germicidal lamps are all fused silica electric light source products. Germicidal lamps are widely used in the catering industry and the medical and health industries. .

(2) Optical fiber industry

Fused silica material is not only an important basic material for optical fiber preforms, but the entire process of optical fiber production is also inseparable from fused silica products. Good raw materials are the guarantee for the production of stable quality optical fiber products. As an important raw material in MCVD, PCVD and their derivative process technologies, high-purity fused silica substrate tubes have strict requirements on size and purity. For example, the deposition of new layers of substrate tubes requires light guide grade. At present, although some of the quartz glass products for optical fibers in our country have reached a certain level, there is still a lack of cutting-edge products such as high-purity, high-precision quartz glass base tubes and outer tubes.

(3) Aerospace industry

Fused silica has a low thermal expansion coefficient and excellent radiation resistance, so it is widely used in the aerospace industry. The code-named 7971 fused silica developed by Corning Corporation in the United States has an average linear thermal expansion coefficient of zero in the range of 0~200℃. It has good thermal stability, low density, good rigidity and good polishing performance. This fused silica can be used to make mirror blanks with a diameter of 3.96m. For large astronomical telescopes. Ultraviolet radiation resistant fused silica can filter ultraviolet rays to protect internal sensors. Fused silica is widely used as a structural part in spacecraft and space shuttles.

(4) Electronic information, semiconductor industry

With the rapid development of my country’s electronic information, semiconductor, and integrated circuit industries, the fused silica manufacturing industry has risen rapidly. For example, the fused silica diffuser used in the key processes of doping, diffusion, oxidation, and annealing of monocrystalline silicon wafers; quartz bell jars used in the epitaxy process of silicon wafers; stents used in the pickling and ultrasonic cleaning of silicon wafers; control units Quartz crucible used in the crystalline silicon process, etc.

(5) Radar industry

The propagation speed of ultrasonic signals in fused silica is lower than that of metals, and the delay temperature coefficient is lower. It can be used as ultrasonic delay glass for radar applications. Ultrasonic waves can be delayed by more than 1 microsecond through multiple reflections of large polygonal fused silica. The reflected radar signal can be used to determine the orientation of a moving target, which has practical application value.

(6) Chemical industry

Fused quartz has the characteristics of acid resistance, high temperature resistance, and high chemical purity. It is an ideal material for the production of chemical equipment. The laboratory rectified water is produced by a quartz glass rectification tower.

(7) Smelting industry

Fused silica is an indispensable material in the smelting industry. Fused silica can withstand a temperature difference of 300°C and is used to produce high-temperature observation windows for industrial furnaces.

(8) Precision instrument industry

Fused silica has good chemical stability and low thermal expansion coefficient, and can be used to manufacture precision instruments, such as interferometers, wavelength meters, gyroscopes, gravimeters and other high-precision instruments.

Disclaimer: The above information comes from the Internet, if there is any infringement, please inform and delete it.