A hand-held fiber laser welding machine is a new generation of laser welding equipment that belongs to non-contact welding. Its working principle is that the laser beam with high energy intensity is irradiated directly on the surface of the material. Through the interaction between laser and material, the material is melted inside and then cooled and crystallized to form a weld.

Hand-held welding is portable operating equipment.

It is also a kind of precision welding equipment, but it can be used freely and flexibly in a variety of environmental applications.

It can be easily applied in all types of environments and has higher professional standards and reliability.

The professional production goal of a hand-held welding machine has the advantages of high standards and specialization.

At the same time, it is also a practical and humanized design in the process of ensuring accurate welding targets.

At the same time, it improves the welding defects in traditional welding processes, such as edge biting, incomplete penetration, stomatal density, and cracks.

The seam of the hand-held optical fiber laser welding machine is smooth and beautiful, which reduces the subsequent grinding process and saves time.

High cost, fewer consumables, and long service life that is why they are popular in the market.

You can take a look at the product show On YouTube.

Advantages of handheld laser welding

Wide welding range:

Handheld welding head equipped with 5m-10m original optical fiber, overcoming the limitations of the workbench space, allowing outdoor welding and long-distance welding.

Easy to use and flexible:

Handheld laser welding is equipped with moving pulleys, a comfortable grip, and the ability to adjust the work position at any time. There is no need to fix the work position; it is free and flexible, and suitable for a variety of work environment scenarios.

A variety of welding methods:

It can achieve any angle of welding, stick welding, butt welding, vertical welding, flat angle welding, internal angle welding, external angle welding, etc.. It can be a variety of complex welding seams of the workpiece, larger workpiece irregular shape, and achieve any angle of welding. In addition, it can also complete the cutting, welding, and cutting free switch and change the welding copper nozzle for the cutting copper nozzle, which is very convenient

Good welding effect:

Handheld laser welding is thermal fusion welding; compared to traditional welding, laser welding has a higher energy density, can achieve a better welding effect, welding area heat impact is small, not easy to deform, blackening, backtraces of the problem, welding depth, full melting, solid and reliable, the strength of the weld reaches or even exceeds the base material itself, which is not guaranteed by ordinary welding machine

The operation is simple, and the high-quality welding effect can be easily realized.

Suitable for small-scale production:

Compared with automatic equipment deployment, hand-held laser welding machine has a lower production compliance rate.

However, for workshops engaged in small-scale processing or non-large-scale welding, manual laser welding is a better choice; there is no need to set up equipment to deploy the welding table, taking up small space, aiming at the diversification of welding products and flexible product shape. A laser hand-held welding machine can fully meet the needs of this kind of production.

Low maintenance cost:

In hand-held laser welding, there is no need to add welding wire, and there is basically no consumable material cost.

The pump source’s life is more than 100,000 hours, and it is basically maintenance-free, saving effort and worry.

Comparison between hand-held laser welding machine and argon arc welding

Thickness requirement

Thin plates cannot be welded by argon arc welding or gas shielded welding.

The heat effect is big, below 1mm, scrap directly.

Hand-held laser welding is suitable for thin plate welding within 3mm, more than 4mm, which is basically the specialty of argon arc welding.

Suitable process and function.

Argon arc welding is suitable for reinforcement or fasteners, such as plates or pipes above 4mm. Bed welding does not require precision and beauty; it is only used for reinforcement and load-bearing, and then it has sufficient advantages.

You can always manage, accumulate thickness, and strengthen the workpiece itself, but do not pay attention to beauty; product added value is also different from this.

In this case, there is no need for laser welding.

Hand-held laser welding: suitable for appearance parts, support parts, and structural parts.

There is a case of missing or false welding.

Argon arc welding: repeated spot welding on the original welding workpiece will create a pit; a point is a pit.

In the later stage, if the welding is not good, it can not be amended; the more it is mended, the easier it is to collapse, and the cost of large parts is very high. If it is scrapped, the cost is very high.

Hand-held laser welding: It can repair welding, and people can be flexible welding. However, according to the actual needs, fill welding wire, later slightly polished below.

Thermal influence condition

Argon arc welding produces a great heat impact and slow heat dissipation. The solder joint to the metal part is all red, and it is very hot.

Hand-held laser welding: basically no thermal effect, fast heat dissipation.

Mobility flexibility

Argon arc welding: 3 meters long, dragging an electric chassis (gun body) is not convenient to move.

Hand-held laser welding: 5-20 meters long, easy to move.

Risk coefficient

Argon arc welding: big spark, easy to splash on body and face.

Hand-held laser welding: no sparks, laser protective glasses.

Main Parts

Laser source: 1000w ,1500w , 2000w

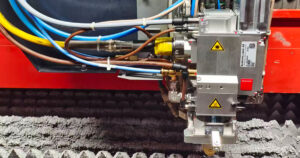

Laser Head: Double Vibrating mirror

Water chiller: S&A or HL water chiller

PLC system: Qilin

Wire Filter Machine

Welding Thickness

| No | Laser power | SS/CS | Alu | Voltage | Gas |

| 1 | 1000w | 0.4-2.5mm | 0.3-1.5mm | 220v | N2<0.1mpa |

| 2 | 1500w | 0.4-3.3mm | 0.3-2.2mm | 220v | N2<0.1mpa |

| 3 | 2000w | 0.7-3.0mm | 0.5-3.0mm | 380v | N2<0.1mpa |

SPECIFICATIONS

| Laser power | 1000 / 1500 / 2000 watts |

| Laser source | Raycus / IPG/MAX |

| Welding head | Wobble welding head / Normal welding head |

| Laser frequency | 50Hz-5000Hz |

| Adjustable power rate | 5 to 100% |

| Beam quality | 1.1 |

| Electric power | 220V50HZ / 380V 50Hz |

| Wavelength | 1070±5nm |

| Consumable part | Protection lens,focusing lens nozzle |

| Fiber leangth | 15m Standard |

| Cooling method | Water chiller |

| Dimension | 930x600x800mm |

| Gross weight | 200kg |

If you want to know more details, feel free to contact us!