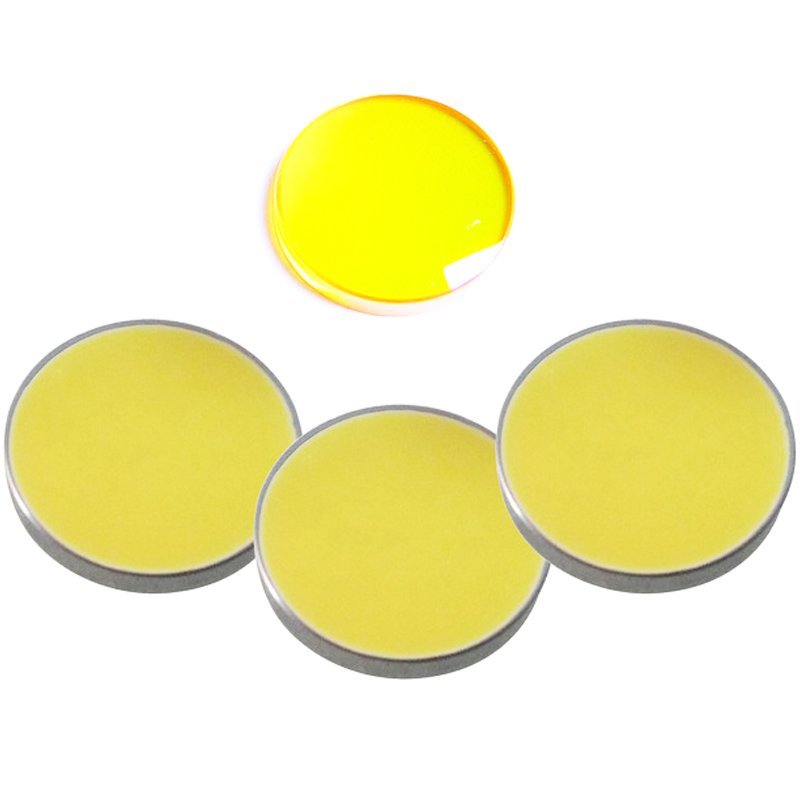

CO2 Laser Mirrors for 25 to 200 Watt industrial lasers are made from silicon with an average reflectance >99.5 to 99.7% @10.6 µm and 45° AOI or from molybdenum which provides 98% average reflectance and is more durable for use in applications that require frequent cleaning.

Si is perfectly acceptable for a mirror. The vast majority of mirrors used by ULS, Trotec, Epilog, etc. are all Si, and they’re good for hundreds of Watts.

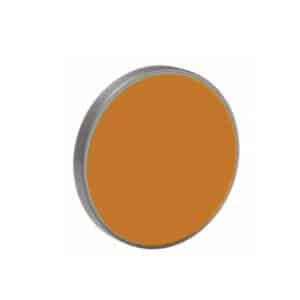

Molybdenum (Mo) Mirrors for CO2 Lasers Uncoated solid Molybdenum (“Moly”) mirrors are simply the toughest, most durable, longest lasting laser mirrors available.

Molybdenum has the lowest thermal expansion of any commercially used metal and will withstand extreme temperatures without significantly expanding or softening. It has a Melting Point of 2,623 °C (4,753 °F). Silicon mirrors are workable, but they’re not quite as durable.

Molybdenum mirrors are highly durable. but there has not a high reflection rate.

Parameters Chart:

| Material | Diameter(mm) | Thickness(mm) | Coating |

| Silicon | 20 | 3 | MMR/UC@10.6um

ATFR/UC10.6um |

| 25 | 3 | ||

| 30 | 4 | ||

| 38.1 | 5/8 | ||

| Molybdenum | 19 | 3 | Uncoated |

| 20 | 3 | ||

| 25 | 3 | ||

| 30 | 3 | ||

| 38.1 | 5/8 |