Hand-held welding is a piece of portable operating laser equipment.

It is also a precision welding machine, but it can be used freely and flexibly in various environmental applications.

It can be easily applied in all working conditions and has higher professional standards and reliability.

The professional production goal of hand-held welding machines has the advantages of high standards and specialization.

Advantages of hand-held laser welding machines

Wide welding range:

Hand-held welding machines are equipped with 5-10m original fiber wires, which can overcome the limitations of workbench space and can be welded outdoors and over long distances.

Convenient and flexible to use:

Hand-held laser welding machines are equipped with a mobile pulley and a comfortable grip; they can adjust the station at any time, have no fixed position, are free and flexible, and are suitable for all kinds of working scenes.

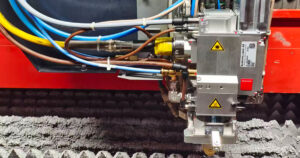

A variety of welding methods:

It can achieve any angle of welding, stick welding, butt welding, vertical welding, flat fillet welding, inner fillet welding, external fillet welding, etc., can weld a variety of complex welds, large workpieces irregular shape, and achieve arbitrary angle welding.

In addition, you can also complete the cutting, welding cutting is free to switch, as long as the welding copper nozzle is for cutting copper nozzles, it is very convenient for you.

Welding performance is good:

Hand-held laser welding is hot fusion welding. Compared with traditional welding, laser welding has a higher energy density and can achieve a better welding effect. The thermal influence of the welding area is small; it is not easy to deform or blacken, and there are traces on the back. The welding depth is large, the melting is sufficient, firm, and reliable, and the weld strength reaches or even exceeds the base metal itself, which can not be guaranteed by ordinary welding machines.

Suitable for small-scale production:

When compared with automatic equipment deployment, hand-held laser welding machine has a lower production compliance rate.

However, for workshops engaged in small-scale processing or non-large-scale welding, manual laser welding is a better choice; there is no need to set up equipment to deploy the welding table, taking up small space, aiming at the diversification of welding products and flexible product shape. Laser hand-held welding machines can fully meet the needs of this kind of production.

Low maintenance cost:

In hand-held laser welding, there is no need to add welding wire, and there is basically no consumable material cost.

The life of the pump source is more than 100000 hours, and it is basically maintenance-free.