UV laser has the characteristics of 355nm wavelength, small spot, narrow pulse width, multi-wavelength, fast speed, good penetration, less heat, large output energy, high peak power, and good material absorption, which belongs to the cold light source. It is also known as “cold processing”. It can be better absorbed by materials, and the damage to materials is less. Compared with conventional CO2 lasers and fiber lasers, they can meet the vast majority of industrial precision processing requirements.

At present, based on a variety of performance advantages, solid-state UV lasers are widely used in various industries and become one of the mainstream industrial-grade lasers.

In our daily life, we will come into contact with all kinds of trademark marks, including metal or non-metal, some with words and some with patterns, such as beauty logo, mobile phone Apple logo, keyboard keys, mobile phone keys, cup pictures, and texts, the production date of cans, and so on. At present, many of these marks are marked by ultraviolet lasers.

The reason is very simple, ultraviolet laser marking, fast, no consumables, through the optical principle, can print permanent marks on the surface of all kinds of materials, which is of great help to anti-counterfeiting.

Application field

UV laser has more advantages than other lasers, which can limit the thermal stress, reduce the damage to the workpiece and maintain the integrity of the workpiece during processing.

At present, UV laser is used in the field of enterprise processing, there are mainly four areas, glass technology, ceramic technology, plastic technology, cutting technology.

Glass technology

Glass marking can be used in glass bottle packaging in wine bottles, seasoning bottles, beverage bottles, and other industries, as well as in the manufacture of glass craft gifts, crystal marking.

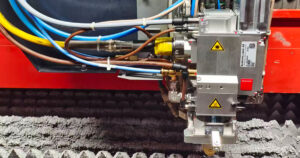

Laser cutting

Ultraviolet laser equipment can be used in many fields of flexible plate production, including FPC profile cutting, profile cutting, drilling, covering film opening window, soft and hard plate uncover and trimming, mobile phone case cutting PCB shape cutting.

Plastic marking

Application: the vast majority of general plastics and some engineering plastics, such as PP,PE,PBT,PET,PA,A BS,POM,PS,PC,PUS,EVA, etc., can also be used in plastic alloys such as PC/ABS and other materials, laser marking of clear and bright handwriting, can be marked black, white handwriting.

Ceramic carving

Application: tableware ceramics, vase ceramics, building supplies, ceramic sanitary ware, tea set ceramics, etc., ultraviolet laser ceramic marking, high peak, low thermal effect, has natural advantages for similar ceramic fragile products, such as etching and carving, cutting is not easy to damage devices, precision technology, reduce the waste of resources.

At present, UV laser equipment with many performance advantages, such as narrow pulse width, multi-wavelength, large output energy, high peak power, and good material absorption, has been used in the ultra-fine processing high-end market. such as mobile phones, cosmetics, drugs, flexible PCB board, and other materials surface marking, marking, as well as silicon wafer microhole, blind hole processing.

With the increase of power, the field of cutting is bound to be more extensive.