Fiber Laser cutting machines are widely used in industry now. They are one of the necessary machines for many industries and enterprises. They are commonly used in sheet metal processing, advertising sign production, high and low-voltage electrical cabinet production, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, glasses industry, spring sheets, circuit boards, electric kettles, medical microelectronics, hardware, knife measuring tools, and other industries.

How can you do maintenance if you have a fiber laser cutting machine? we will give you some tips :

Clean the cutting table:

After daily use, clean the metal residue and dust on the cutting table in time to avoid deformation of the cutting table or affect the cutting accuracy.

Clean the guide rails and gear racks:

Clean the guide rails at least once a week and apply lubricating oil to ensure the smooth operation of the laser machine. At the same time, the gear racks should be cleaned regularly and coated with unsalted butter to prevent the accumulation of solid smoke and reduce wear. The laser cutting machine should be prevented from overloading to avoid damaging the guide rails. According to the carrying capacity of the laser machine, the cutting tasks should be arranged reasonably to avoid overweight cutting.

Clean the protective lens:

Before cutting every day, check whether the protective lens is clean. If there is dust or contaminants, use isopropyl alcohol or analytical pure (alcohol purity is more than 99.5%) to clean the protective lens. when you clean the lens please use dustproof tape to stick on the cutting head. Following the manufacturer’s recommendations and using the correct protective lens and nozzle can extend the span life of the cutting head.

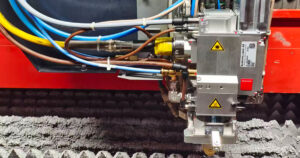

Check the cutting head:

The maintenance of the cutting head is very important. It is necessary to check the condition of the cutting head regularly, including whether there is dust inside the cutting head, whether the protective lens is clean, and whether the nozzle is unobstructed. If problems are found, they need to be cleaned and replaced in time.

Adjust the focus: The focus position has a great influence on the cutting quality, and the focus position should be checked and adjusted regularly. According to different cutting materials and thicknesses, choose the appropriate focus position to obtain better-cutting results.

During cutting progress, avoid collision between the cutting head and the workpiece or other objects to avoid damage to the cutting head.

Check the optical fiber and wires:

Check the optical fiber and wires regularly for damage. If necessary, replace them in time to avoid affecting the normal operation of the equipment.

Check the cooling system:

The fiber laser cutting machine needs to use cooling water to reduce the temperature of the laser cutting head and laser resonator, so it is necessary to regularly check whether the cooling system is operating normally, including the flow and water quality of the cooling water.

Check the coolant: Check the coolant level and quality regularly. If the coolant is insufficient or deteriorated, add or replace it in time. Choose the right coolant to ensure that it has good cooling and anti-rust properties.

Control the temperature: The cooling system should maintain a suitable operating temperature to avoid the impact of excessively high or low temperatures on the machine.

Regularly replace consumables:

Some consumables such as cutting nozzles, ceramic holder, protective lenses, etc., need to be replaced regularly to ensure cutting quality and efficiency.

The daily maintenance of the fiber laser tube cutting machine needs to be regular, meticulous, and comprehensive, including cleaning, inspection, replacement of consumables, and other aspects. Only in this way can ensure that the machine is guaranteed and the span life is extended, while also improving the cutting quality and efficiency.