Cutting quality in a great extent depends on whether the lens is in the middle. If the lens is not in the middle, the laser beam may contact with the nozzle or inner wall to produce high-temperature deformation. Lens alignment operation should be considered when the nozzle is replaced or the cutting quality declines.

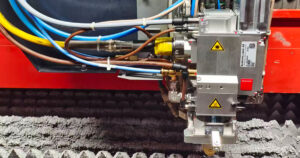

Lens alignment of laser cutting head can be finished by adjusting the focus lens, X-Y direction. The X/Y adjusting knob is located above the bottom cover glass as shown below. Adjusting the 2 knobs until the beam is located in the middle of nozzle. Make sure the laser beam output from the center of the nozzle.

A method commonly used is the tape dotting method as below:

Tools: 1.I nternal 6-angle screwdriver 2. nozzle 3. Scotch tape

To align the laser through the nozzle, follow these steps:

- Turn on the laser machine and launch the software.

- Affix clear scotch tape or clear packing tape to the bottom of the nozzle on the laser head, ensuring that it fully covers the nozzle hole.

- Apply pressure to imprint the nozzle opening shape onto the tape, then turn on the shutter.

- To pulse fire the laser, click the “Laser” test (power 10%). Ensure that protective glasses is worn, and that there is no flammable material beneath the nozzle.

5.Use a Scotch tape stick on the nozzle and make the laser out twice to shoot the tape.

▪ Fix the cutting head with a big size nozzle (tip size shall be larger than beam size) or adjust to nearly zero focus.

▪ Pick a scotch tape, flatten it, and stick it to the nozzle tip.

▪ Open the red light of the laser. Find and observe the position of the red light in the scotch tape. ▪ Shoot laser at low power to check beam penetration size. Beam penetration shall be circle and located in the nozzle tip center.

▪ Adjust the 2 X/Y adjusting knobs to get the beam aligned. The max X/Y adjusting range is roughly from -1.5mm to +1.5mm.

▪ Tear off the tape and check the shooting hole position in the tape.

▪ Repeat the above steps to find a relatively centered position.

Here is a video for your reference. https://www.youtube.com/watch?v=W6z86ZMXkXU

1 thought on “How do you adjust the laser to the center of the nozzle?”

how to center 100percent accurate centering