The metal&Non-metal laser machine is laser equipment that can cut both metal and non-metal materials: suitable for metal, stainless steel, carbon steel, and non-metallic materials (acrylic, plexiglass, wood products, two-color plate, density plate, etc.)Generally, the laser machine for cutting metal is fiber laser, and co2 laser machines are used for non-metallic materials. If customers need to cut metal materials and nonmetal materials, they need to buy a fiber laser cutting machine and a co2 laser cutting machine, which increases costs, but also requires a larger space to install the machines. if you only stainless steel plates less than 1mm. it is unnecessary to buy an expensive fiber laser cutting machine because we provide you with a laser hybrid cutting machine, which can well cut metal materials within 1mm, in addition, you can also cut 30mm acrylic, 18mm medium density fibreboard, and other non-metal materials.

Main accessories

1. Metal cutting servo system.

2. The service life of a high-end Co2 laser tube is 10000 hours, and the warranty time is as long as12 months.

3. High precision industrial synchronous belt with steel wire, longer service life.

4. Industrial water cooling system.

5. Operating system, optional remote control.

6. Raytheon stepper motor and drive, higher stability.

7. The new Taiwan linear guideway makes the movement smoother.

Technical parameters

Processing format: 1300x900mm.

Laser power: 150W-300W.

Cutting speed: depending on material and thickness.

Repetitive positioning accuracy: ±0.05mm.

Cutting thickness: metal material: ≤ 1.5mm (non-metal depends on material).

Power consumption of the whole machine: ≤ 4KW.

Power demand: AC220V 50Hz/60Hz (can be met by direct ordinary power grid).

Machine weight: 320kg.

Appearance size: 1865mmX1635mmX1190mm.

Functional features

- Ultra-low-cost, laser consumption per hour is only 0.5 kilowatt-hours 1.5 kilowatt-hours.

- High performance, Beijing Reci laser, stable performance, and long service life.

- High speed, high efficiency, cutting sheet can reach 2.6 meters per minute.

- The whole machine is guaranteed for one year and the laser tube for 12 months.

- The quality of the cutting edge is good, the deformation is small, and the appearance is smooth and beautiful.

- Can design all kinds of graphics or text real-time cutting at will, the operation is simple, flexible, and convenient.

Mainly Advantages

- Mixed-cut:metal-Stainless steel, carbon steel, and non-metal-acrylic, board, etc.

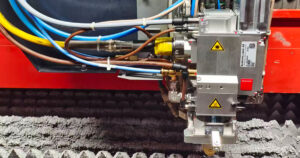

- High precision: Imported servo motor with imported ball screw transmission greatly improve the response speed and cutting precision of equipment, extend the time of using

- High precision and Good stability: With precision ball screw transmission mechanism and optimized NC system control, it can meet the precision parts processing, stable dynamic performance, and long span life.

- The cutting section with good quality: Mechanical follow-up cutting head system, cutting head always follows the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again. It can adapt to flat or curved surface sheet cutting.

- Adopt sealed co2 laser tube, main consumable items are electric energy,water-cooling, auxiliary gas, and laser light.

- Simple structure, easy to operate, stable laser device, and low maintenance cost.

Laser Processing Chart

Remember there is a power/speed ratio correlation. The more you increase the speed the less power is focused on the area.

For example, if you want an engraving to look darker you don’t always have to increase power, you can slow down the speed. The same goes for cutting, if you didn’t get a good cut, you can reduce the speed. If you want to increase the speed you will also have to slightly increase power. This power/speed ratio correlation is the fundamental basis of engraving

and cutting.

We don’t recommend surpassing 70% max power for any project. If your machine is well-tuned and the software settings are correct you can get the desired cuts or engraving quality with no more than 50-60% max power. Running your machine above 70% max power or above 20 amps constantly, will shorten the lifespan of your laser tube.

It is important to note that using the machine constantly between 70%-99% max power will drastically reduce the lifespan of the laser tube.

| Material | W6 (150W) | W8(180W) | YL(260W) | YL(300W) |

| Acrylic | 20mm | 25mm | 30mm | 30mm |

| Plywood | 15mm | 20mm | 20mm | 20mm |

| MDF | 10mm | 15mm | 20mm | 20mm |

| Stainless Steel | 0.5-0.6mm | 1mm | 1.5-2mm | 1.5-2mm |

| Carbon Steel | 0.5-0.6mm | 1mm | 1.5-2mm | 1.5-2mm |

| Material | Cut | Material | Cut |

| Wood | √ | Pressboard | √ |

| Acrylic | √ | Rubber | √ |

| Fabric | √ | Wood Veneer | √ |

| Glass | Fiberglass | √ | |

| Coated Metals | √ | Painted Metals | √ |

| Ceramic | Tile | ||

| Delrin | √ | Plastic | √ |

| Cloth | √ | Cork | √ |

| Leather | √ | Corian | √ |

| Marble | Stainless steel | √ | |

| Matte Board | √ | Carbon Steel | √ |

| Melamine | √ | Galvanized Steel | √ |

| Paper | √ | Titanium | √ |

Generally speaking, Mixed laser cutters are highly cost-effective laser cutting machines, which can control metal materials and non-metal materials freely. For the current advertising industry, it is still a good choice.